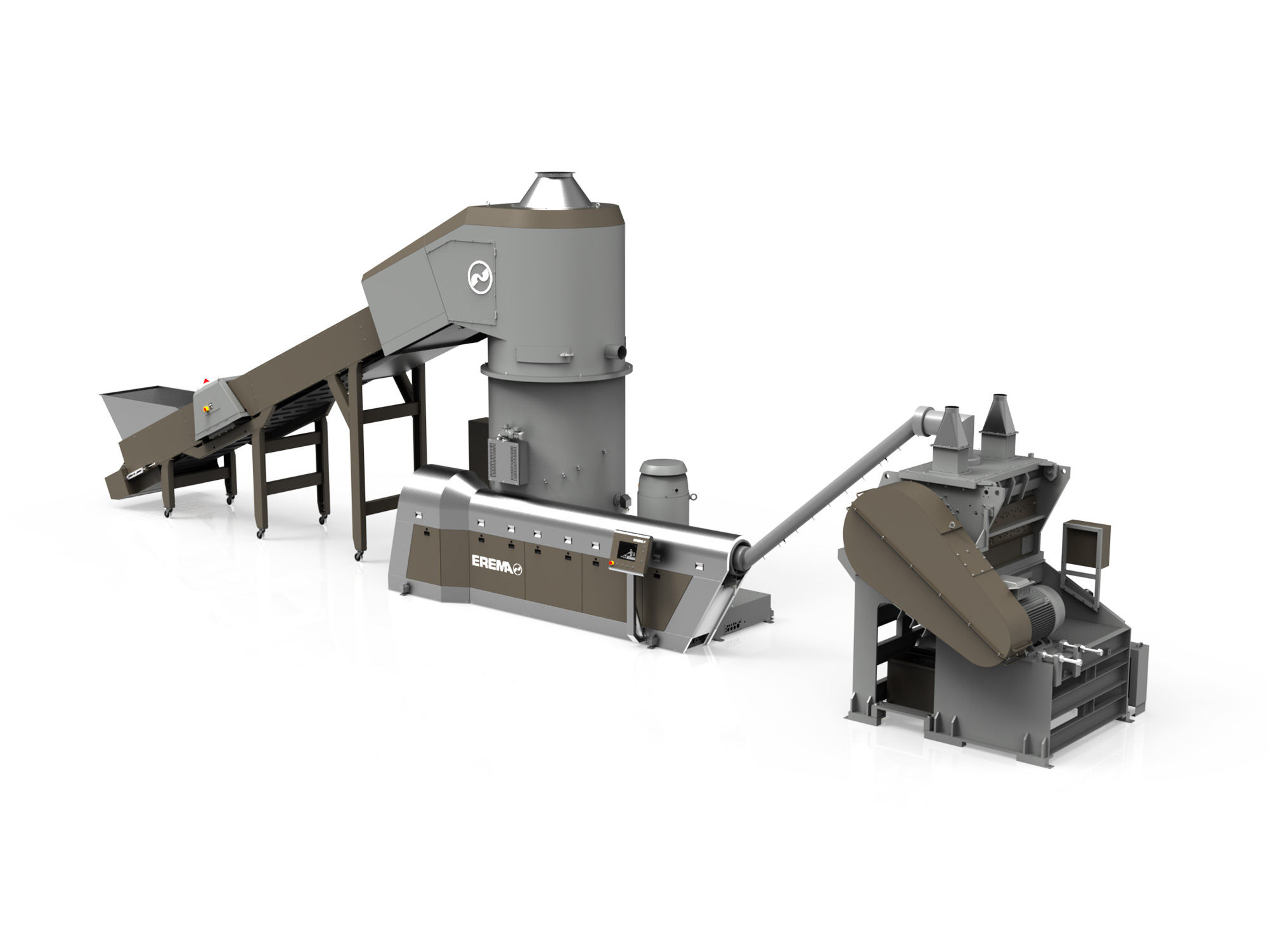

AGGLOREMA®

High-quality agglomerates with the decisive PCU advantage.

Simple, robust, efficient – the new AGGLOREMA from EREMA turns highly contaminated, heterogeneous post consumer waste into premium-quality agglomerates – and saves energy in the process. These free-flowing agglomerates are the perfect feedstock for chemical recycling and guarantee reliable and logistically optimised input to the reactor.

Flexible and robust: From low to high bulk density

The innovative AGGLOREMA system delivers maximum flexibility. The machine has no difficulty whatsoever processing heavily contaminated waste streams such as film rejects with low bulk density (from 30 kg/m³) and high, fluctuating moisture levels from sorting facilities. These materials are turned into premium-quality agglomerates with a high bulk density.

EREMA Preconditioning Unit with patented Counter Current® technology

The new AGGLOREMA reliably and efficiently handles even very low-bulk-density materials and materials with a widely varying composition – in terms of polymer, geometry and moisture. This is made possible by a unique combination of technologies: the EREMA Preconditioning Unit (PCU) with its patented Counter Current® technology and a specially developed extruder screw. The result: a stable, robust process even when the quality of the input materials is inconsistent.

The material is homogenised, preheated, dried and continuously fed into a short extruder without upstream drying. Whereas conventional agglomeration systems quickly reach their limits if the feed material has a low bulk density or fluctuating parameters, the AGGLOREMA has no difficulty whatsoever meeting these challenges.