Plasticising technology

Lower temperature, less energy. The gentle way to recycle PET.

Gentle on the material. Strong in terms of effect.

For high throughputs in PET recycling.

Whether VACUREMA® Basic, Advanced or Prime, or VACUNITE® - EcoGentle® is the ultimate plasticising technology for PET recycling. It combines gentle melt treatment with signifi cantly reduced energy consumption in a unique way. This saves you money on production costs. For high cost effectiveness, productivity and top-quality rPET end products.

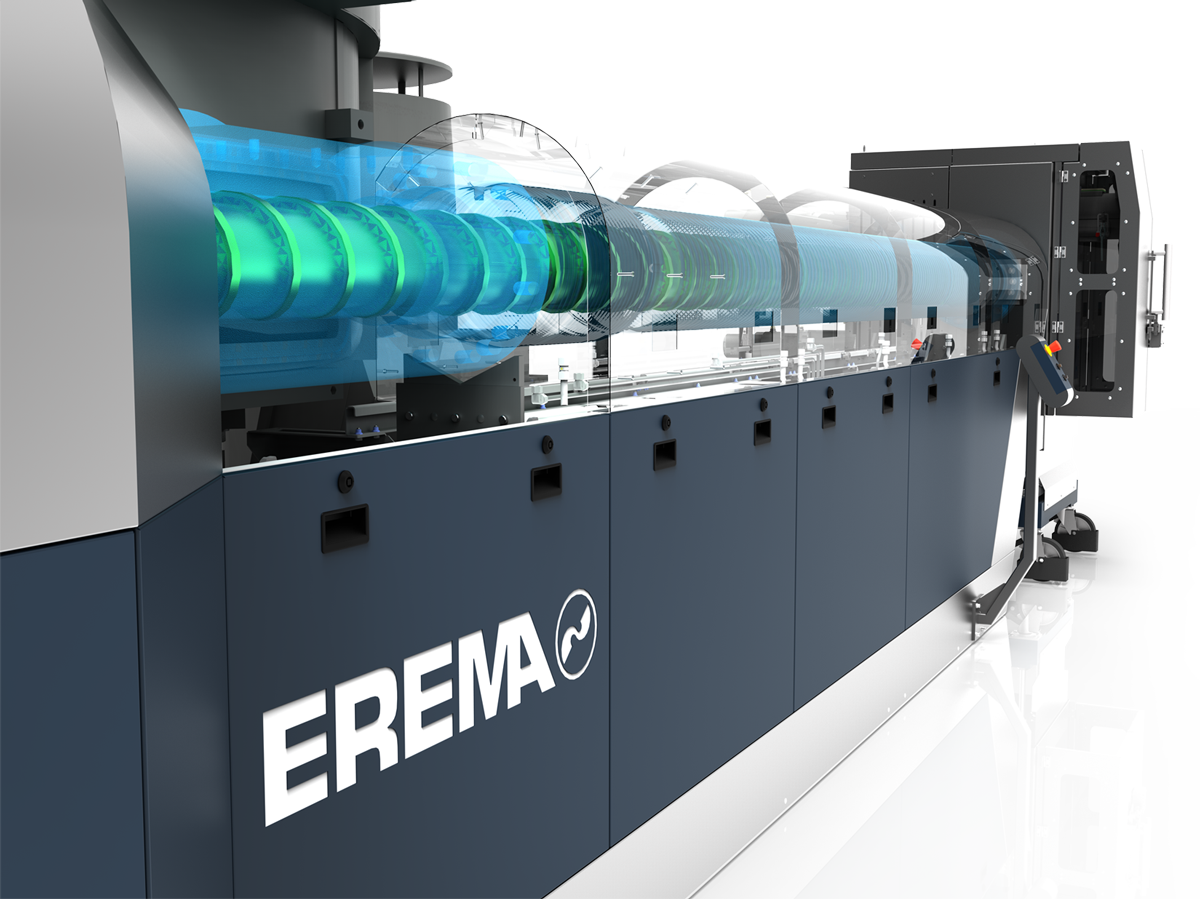

Extrusion the gentle way

Newly developed EcoGentle® plasticising technology, in combination with EREMA's proven Counter Current® technology, ensures perfect interaction between the feed section and the extruder screw. Temperature and energy requirements are greatly reduced, while at the same time improving melting and mixing performance in the plasticising unit.

The core elements of the innovative EcoGentle® technology are the adjustment of compression ratios for better solids handling behaviour, the targeted utilisation of shear flows in combination with elongation flows, and a number of other process and rheological optimisations. The perfectlymatched interaction between the shear and elongation flows increases both the melting performance and the dispersive and distributive mixing capacity in the plasticising unit.

Wider process window, more stable operation

The result is particularly gentle plasticising combined with high melt homogeneity and a wide process window for more stable operation. Variations in parameters such as the bulk density of the input material, viscosity or temperature of the PET flakes can be compensated as part of the stable process.

EcoGentle® stands for a particularly gentle method of plasticising at lower temperature that saves energy. The much lower melt temperature has a positive effect on the quality of the melt and the quality of the final rPET pellets.

Your benefits

Economical and technically better.

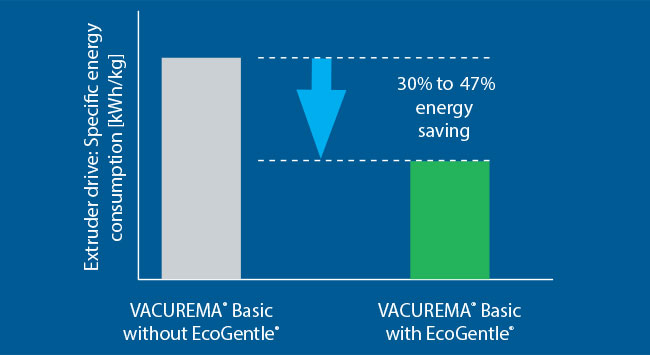

Extruder drive:

Previous top energy efficiency further dramatically improved

Compared to a VACUREMA® Basic with conventional plasticising unit (without EcoGentle®), which previously already achieved the best energy efficiency values, a VACUREMA® Basic with the new EcoGentle® plasticising unit consumes between 30% and 47% less energy for the extruder drive* - depending on the material properties (specific energy consumption kWh/kg).

PET recycling goes X-Large Up to 6,000 kg/h

With the new EcoGentle® plasticising unit.

Get the maximum out of your PET recycling plant. With new EcoGentle® plasticising technology, you reach a new dimension. Up to 6,000 kilograms of the fi nest rPET pellets per hour. Maximum energy efficiency, process stability and gentle processing

EcoGentle®: The new dimension in PET recycling

Big, bigger, energy saver.

This is the superlative of the new EcoGentle® plasticising unit from EREMA. For highest throughputs the smart way.