Made easy!

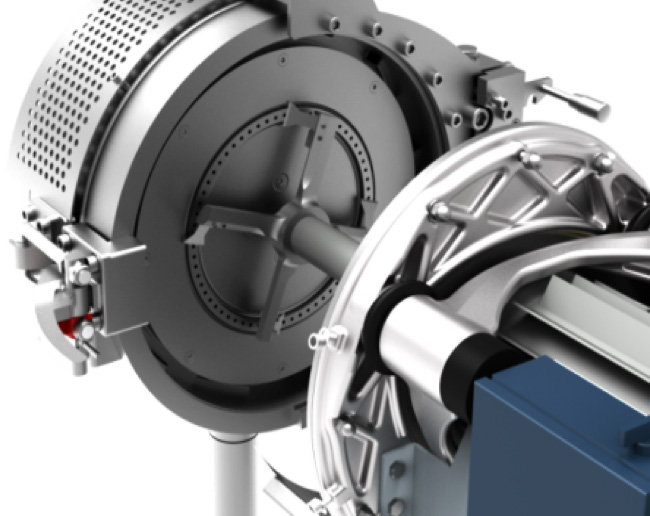

Hot die face pelletising systems with Direct Drive technology

Simple handling and maintenance have always been the trademarks of EREMA hot die face pelletising systems.

Ongoing development of Direct Drive technology has added even more operational reliability, ease of use and flexibility.

Your benefits.

Economical and technically better.

Direct Drive technology with vibration-free design.

HG Air

Hot die face pelletising systems with air technology

Robust implementation proven again and again. For automatic repelletising of different thermoplastic materials, compounds and wood/plastic composites (WPC). The series HG AIR 80K, HG AIR 120K, HG AIR 120 and HG AIR 240 set new standards in terms of operational reliability, straightforward operation and flexibility.

Your benefits.

Economical and technically better.

ASP

Semi-submerged strand pelletising systems for low-viscosity thermoplastics.

EREMA's semi-submerged strand pelletising systems are used to pelletise technical thermoplastics such as PET. Straightforward operation and minimum labour requirements contribute to the very high degree of operational reliability. Easy start-up, fast cleaning when changing over material and automatic self-feeding if strand breaks occur make these systems indispensable. Integrated crystallisation is also possible for PET.

Your benefits.

Economical and technically better.

ASP-CIC

Compact inline crystallisation.

A system for the integrated and energy-efficient crystallisation of PET or PLA. The melt-filtrated strands are cooled briefly in water and then cut into pellets. The material is then fed immediately into a container. The latent thermal energy inside the pellets is used for crystallisation – without additional energy input required from the outside and without interrupting the process.

Your benefits.

Economical and technically better.