Beaulieu Technical Textiles (BTT), member of the Beaulieu International Group, is an established leader and driving force in the production of technical textiles made of PP, PE and biopolymers. Thanks to COREMA® technology, any production waste – even with spinning oil remains – can be reprocessed to make high-quality recycled pellets. This means that a large portion of it can be reused in the production process.

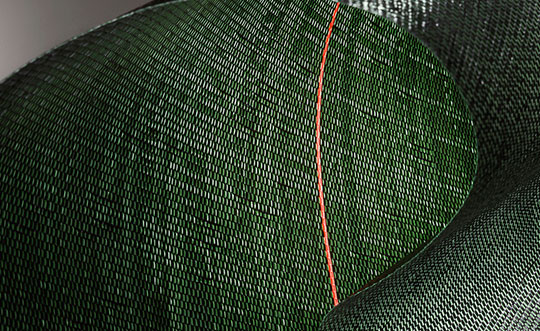

The integrated production process of the polyolefin fibres for the carpet industry (carpet backings), in agriculture and gardening (agrotextiles), civil engineering (geotextiles), the packaging industry (coated and non-coated packaging fibres) and building (as membranes under roofing) also involves the use of spinning oils. The residues of this oil which are left behind in the materials represent a particular challenge when recycling the production waste. This is because the higher the quality of the recycled pellets produced, the higher the share of the recyclate which can be reused in production. BTT has found the optimum solution for this special application in the COREMA® system.

Efficient degassing

In the first step the specially customised COREMA® 1109 T system enables efficient degassing of the (short-chain) spinning oil in the cutter/compactor. The spinning oil remaining in the melt is removed in a further degassing step in the downstream twin-screw extruder which is designed for this purpose. The result is high-quality recycled pellets. Additionally, the low maintenance required and the process stability of the COREMA® system mean that BTT is very satisfied with the new plant.

Significant cost reduction

“We decided in favour of EREMA because our experience with the company and its products had been good in the past. The technology is always state-of-the-art and fit for our applications. EREMA was the clear choice for us,“ explains Bart De Bleeckere, Production and Operations Manager of BTT. Thanks to the COREMA® system, BTT can now recycle all its production waste to make pellets with a satisfying quality – from PP and PE tapes to films and the waste from the spinning process – and significantly increase the share of recyclates in the end product. The benefit is greater production efficiency and with it a considerable reduction in costs.

| Application: | Inhouse & industrial recycling |

|---|---|

| Materials: | PP fibres PP non-woven |

| Product category: | COREMA |

| Modell Details: | COREMA®1109 T |

BEAULIEU TECHNICAL TEXTILES, Belgium

Beaulieu Technical Textiles (BTT), member of the Beaulieu International Group, is an established leader and driving force in the production of technical textiles made of PP, PE and biopolymers. Thanks to COREMA® Technology ...

COREMA with re360 used successfully at INTERSEROH

Using the cascade extrusion system COREMA, the environmental service provider Interseroh produces tailor-made recompounds for very high-quality applications in just one process step.