Directly from PCR-PET flakes to food-safe 100% rPET preforms

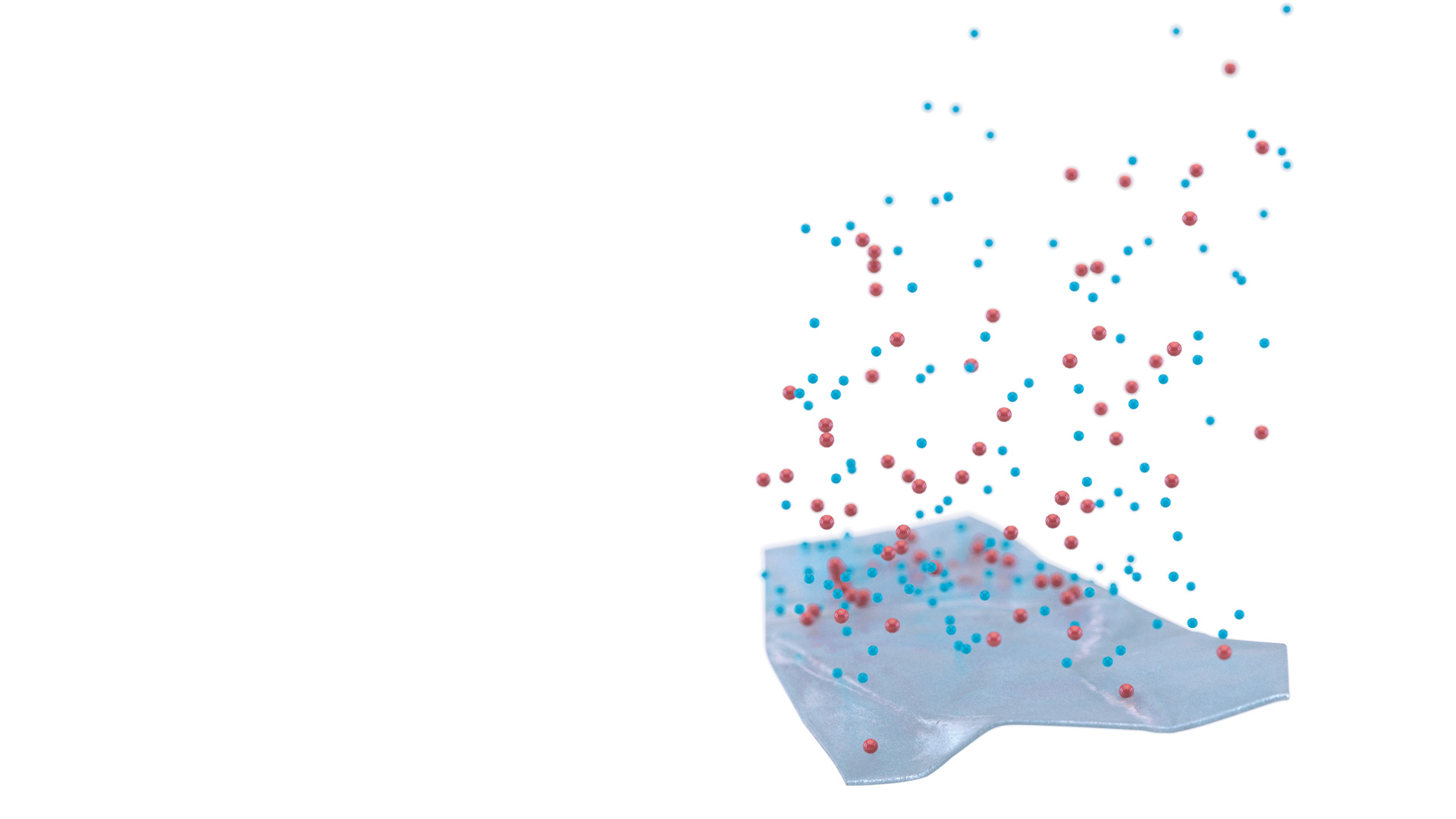

The detour of pellet production is not needed. With the innovative VACUREMA®inline preform system, post-consumer PET flakes are turned into food-safe preforms in a single process step – straight from the melt. These can consist of up to 100% rPET and achieve impressive colour values – there is hardly any yellowing.

The system combines the efficiency advantages of VACUREMA® with the XTREME preform production system from SIPA. By combining injection and compression techniques this system allows you to produce preforms that are up to 10% lighter than even the lightest injection moulded preforms. In a way that gives you massive energy savings.

Innovation through cooperation.

Like EREMA, our partner SIPA also stands for efficient PET solutions. The advantages really make themselves felt in combination with our VACUREMA®inline preform system. Both VACUREMA® and XTREME excel as standalone systems with extremely energy-efficient performance. The combination of the two technologies increases this efficiency even further.

Your practical benefits

Economical and technically better

SafeFlake: Highly efficient decontamination